Billingham bags are 50 years old this year. Nigel Atherton visited their West Midlands factory to talk to founders Ros and Martin Billingham about their journey and how making the world’s most iconic camera bags all began

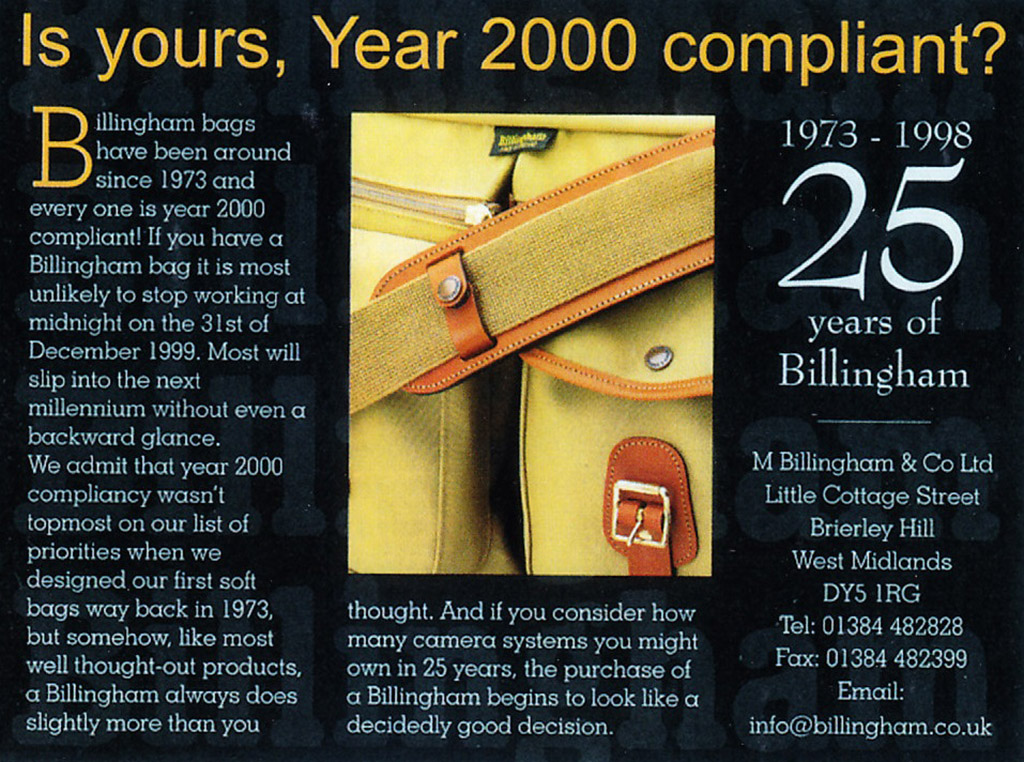

The year 1973 was a good one for creating cultural icons. Pink Floyd’s Dark Side of the Moon was released, and Roger Moore made his James Bond debut in Live and Let Die. Meanwhile in the West Midlands, newly married young couple Ros and Martin Billingham decided to set up a business making bags to supplement the meagre incomes from their day jobs, and along the way created the world’s most iconic camera bag. Fifty years on the Billingham brand is still regarded as the Rolls Royce of camera bags, exported worldwide and used by a who’s who of the biggest names in photography. So how did it all start?

‘I met Martin through photography, explains Ros. ‘I was working at a camera shop and photo studio doing wedding photography and darkroom work, which I really loved. Martin was an amateur photographer at a local camera club, and he used to bring in the 20×16 prints that he had made, to have mounted in the studio. So that’s how we got together.’

The Billingham stand at a photography show at the NEC, 1981. The photo features staff from Billingham and ‘CamCane’ which Billingham used to distribute. Ros Billingham is in the centre of the photo holding a Photo Eventer bag. © Tariq Chaudry

Billingham Bags: the Early days

Although they had known each other for several years Martin was 24 when they got married and bought their first house together. ‘We very quickly realised that we didn’t have a lot of money. We decided that the jobs that we had weren’t good enough, so we thought we’d start a business,’ recalls Martin. ‘We sat down one night and looked at the options. I thought we’d become photographers, but Ros feared we’d end up as wedding photographers and I didn’t fancy that. So we decided that we’d try to make bags, because I’d worked at a company that made canvas and leather fishing bags and they could never make enough of them. I thought perhaps I could make bags for them, but they weren’t interested. But we thought that making fishing bags was still a reasonable idea. So that’s how it all started. We registered the company, borrowed some money and bought a sewing machine.’

It took some time to come up with the design, and source all the materials they required – but eventually they had everything they needed and started making their bags at home. ‘We had a cutting table, first in the garage, and then in the bedroom,’ continues Ros. ‘I can’t use a sewing machine, so I would cut all the pieces of canvas with a big pair of shears, and I’d prepare all the leather and then cut it out with a round leather knife. Then Martin used to sew the bags together.’

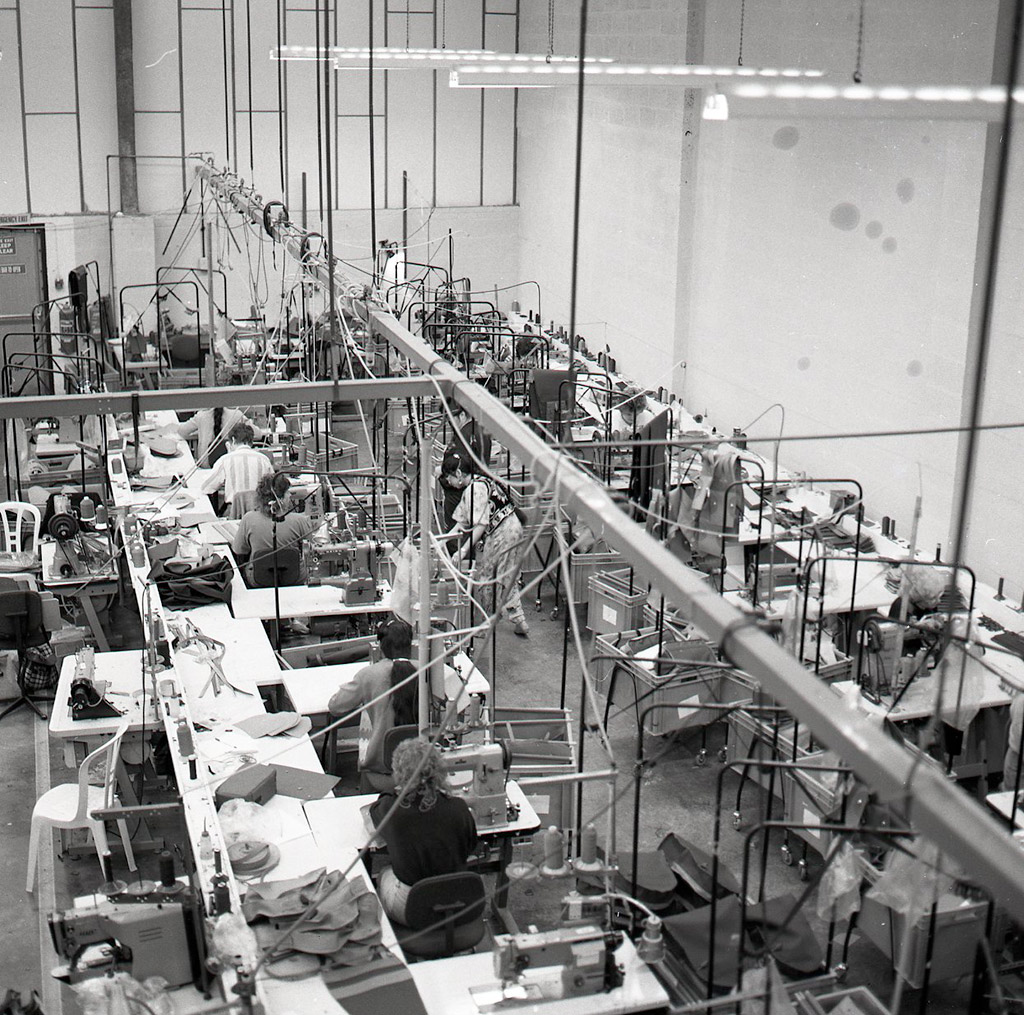

Photo from inside the Lye factory near Stourbridge, which Billingham was based in between 1980 and 1991. Photo: courtesy/copyright of Billingham

They were working part-time at this stage and did lots of other jobs to raise the money to keep the fledgling business going. Martin spent some time working shifts at a chemical factory. Then in 1977 they got a large order for 300 bags from the Alnwick-based fishing company, Hardy Brothers. This gave them the confidence to go full time and move out of their house into their first dedicated business premises – a 500sq ft lean-to, where they worked 12 hours a day. They started getting international orders too, and it was from across the Atlantic that their Eureka moment came.

‘We had started making a lot of bags for an American customer who had a luxury goods brand,’ continues Martin. ‘We found out that he was selling our bags in New York as camera bags, and photographers were buying them in droves. I’ve never been very interested in fishing or shooting, so we looked at each other and thought, “Let’s get back into photography.” It was photography that brought us together. Everything just fell into place.’

Designing their first dedicated camera bag, the System 1, came fairly easily. They were both photographers themselves, and both had used a variety of different equipment, so they had a fairly good idea of what photographers wanted in a bag. Martin kept a notepad and pencil at the side of the bed. He’d wake up in the night with ideas and start drawing and making notes.

‘Cameras and lenses at that time were quite big things,’ says Martin. ‘I thought professionals would need a big bag, and so that’s what we made. We called it the System 1. My father looked at it and said, “That’s far too big. Nobody would want a big bag like that, that’s ridiculous!” Of course he wasn’t a photographer.’

But the initial response from the retail trade to the original khaki and brown leather bag wasn’t a lot better. ‘We had taken the bags around all the camera shops but they weren’t interested,’ recalls Ros. At the time camera bags were all hard boxes and they all said nobody’s going to buy a soft bag and put a camera in it. There wasn’t one shop that would take one and try it.’

Undeterred they started selling by mail order, which proved that there was a market for the bag. Practical Photography wrote a glowing review that boosted the demand further.

A bet from Bailey

A major turning point came in 1980. Martin takes up the story: ‘We had heard about a big photography show at Earl’s Court, London. By that time we were making the System 1 and the smaller System 2. We took a stand at the show and it went fantastically well. Lots of very interesting people came over to the stand to see us. We met Donovan, Lichfield, Bailey and Don McCullin. It was great. David Bailey bet Lord Lichfield that if he could do a certain number of press-ups he would buy him one of our System 1 bags. Lichfield took him up on it and did the press-ups, and Bailey bought him the bag.’

A Bronica camera in a numbered limited edition bundle, which included a Bronica camera and accessories presented in a Billingham hard case. It was the only hard case the firm ever made. Circa late ’90s. Photo: courtesy/copyright of Billingham

‘Having Lichfield using one of our bags was a real endorsement and gave us a great boost,’ adds Ros. ‘It was magical.’ One of the reasons for the interest was, incredible though it may seem today, hardly anyone else was making soft camera bags. ‘We had the whole bag market to ourselves at that time,’ explains Martin.

‘I remember back in the early ’80s one of our customers, the owner of the Tecno chain of camera shops, had a car racing day at Silverstone and he invited me down, and every single one of the motor racing photographers was using a Billingham bag. I thought to myself, it will never get any better than this, because it doesn’t last, does it? But at the time, we had almost no competitors. There was just Tenba and Domke in the US, really.’

By this point the range had evolved into four bags, the System 1, 2, 3 and 4 – essentially different-sized variations on the same bag, and all the same original khaki. In the mid-1980s Billingham introduced a black variant. ‘I went to see Alan Jessop and he wasn’t very happy,’ laughs Martin, ‘because it meant more variations he had to stock.’

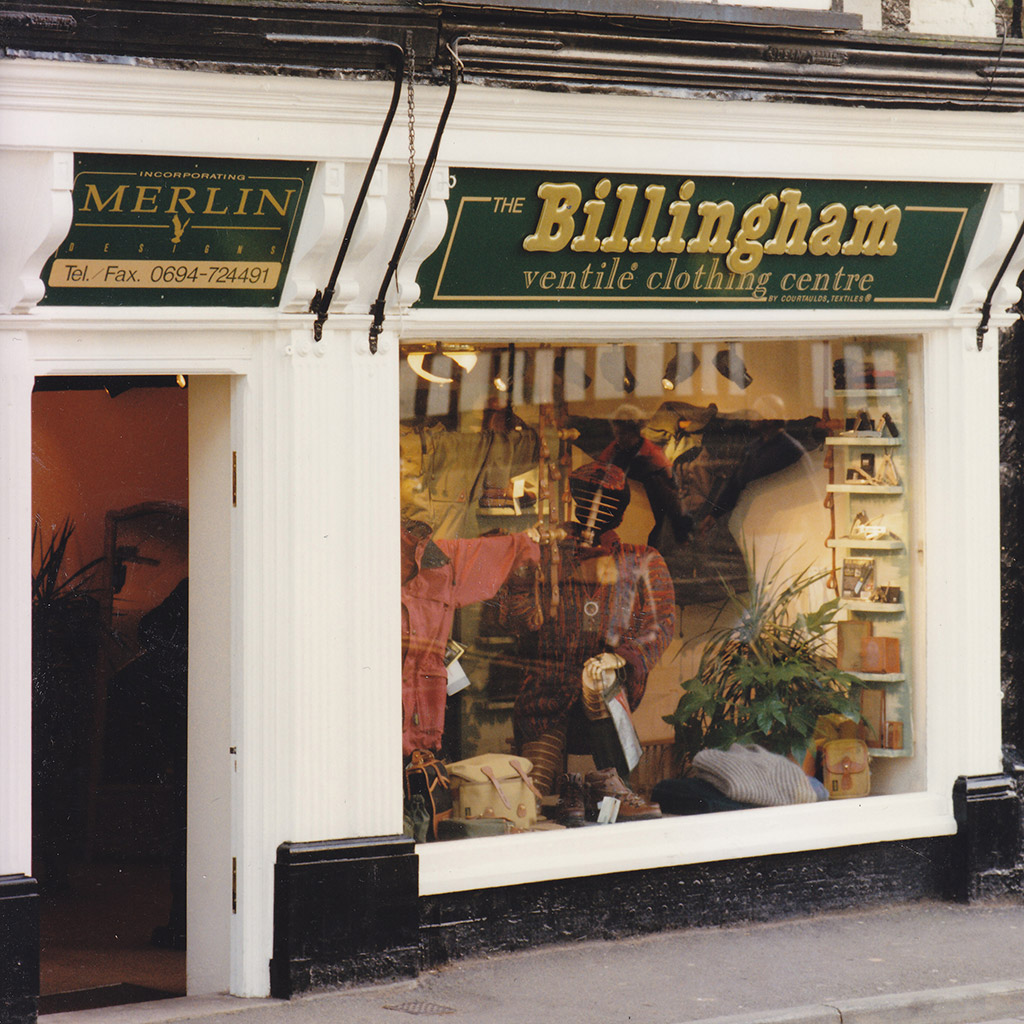

Billingham acquired a Ventile coat manufacturer called ‘Merlin’, its only acquisition of another company. In 1994 they opened a store on Church Stretton high street (near some good hiking spots). However, due to a series of break-ins and the distance from the factory the store was closed. Photo: courtesy/copyright of Billingham

If you build it they will come

Throughout the 1980s the range expanded and evolved, with different formats, shapes and colours, as cameras themselves changed and evolved. Inspiration for new designs comes from a variety of sources. ‘It’s reading magazines,’ says Ros. ‘It’s keeping in touch with people, with photographers. And people come to us with ideas, or they’ll say, I’ve got this equipment, which bag will it fit into? Exhibitions are good for feedback too.’

Martin adds, ‘You have to be careful about doing too much research, because if you ask people what they want, you don’t always get the right answers. If Apple had said “how would you fancy a phone with no buttons on it”, nobody would have wanted it. You have to build it and show them.’

Meanwhile the firm expanded into bigger premises and took on more people. ‘When we started selling camera bags we took the plunge and moved to a new 1,500sq ft unit in a place nearby called Lye,’ says Martin. And then as we continued to expand and sell more bags we moved into the unit next door, which was 4,500sq ft. And then we rented both the units, and the smaller one became the stores.’

Tougher times for Billingham

The 1980s were very good for Billingham but things were about to get tougher. ‘The first ten years were great,’ says Martin, candidly. ‘Then we came into the nineties and the Chinese were starting to export a lot, and we found it more difficult to sell our bags. We’d go to exhibitions and people would say, “Why would I buy this for £200 when I can buy that for £20?” We had to downsize, and it was a real struggle.’

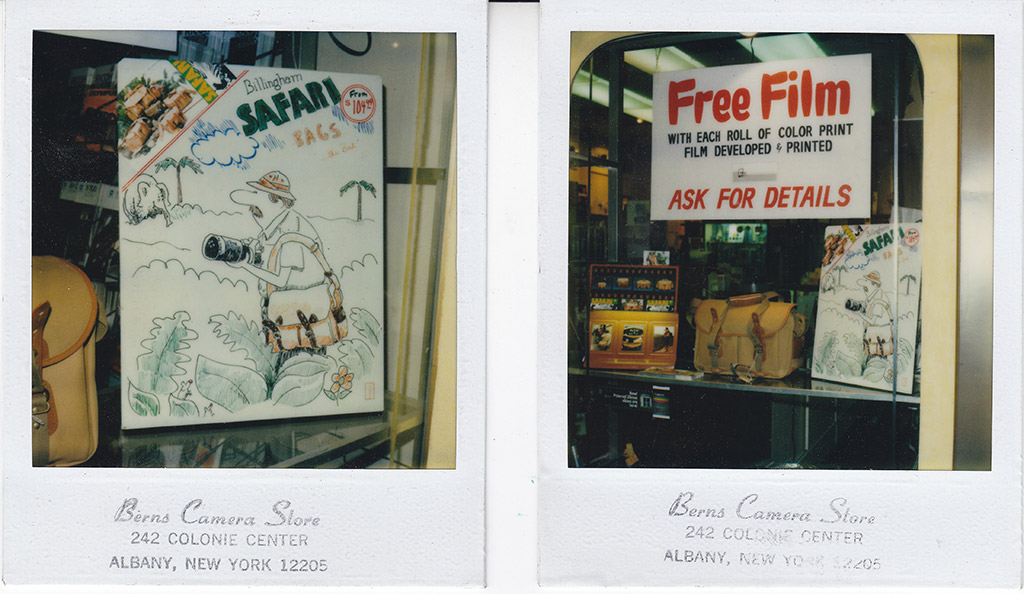

A shop window display at Berns Camera Store in Albany, New York, from the 1980s. Photo: courtesy/copyright of Billingham

Things have picked up since that low point and in 2011 Billingham moved into their current hi-tech premises in Cradley Heath. ‘I got to the stage where I was about to retire and we started getting busy again,’ reflects Martin. ‘We’ve got these new premises now and things are running really nicely. It’s much more pleasurable. We’ve got lovely machines, this place is like a big shed where I can come in and play around with things. It’s fun.’

Martin has a workshop in the factory where he works on designs not only for the bags but also for the machinery that makes the bags. ‘That’s the fun of it. I enjoy making things, but I also enjoy making the same thing over and over. I like to design systems that make it easier for people to make them, like the jigs and things like that.’ These solutions are not always high tech – one of the machines on the factory floor has been modified by a strategically placed yoghurt pot.

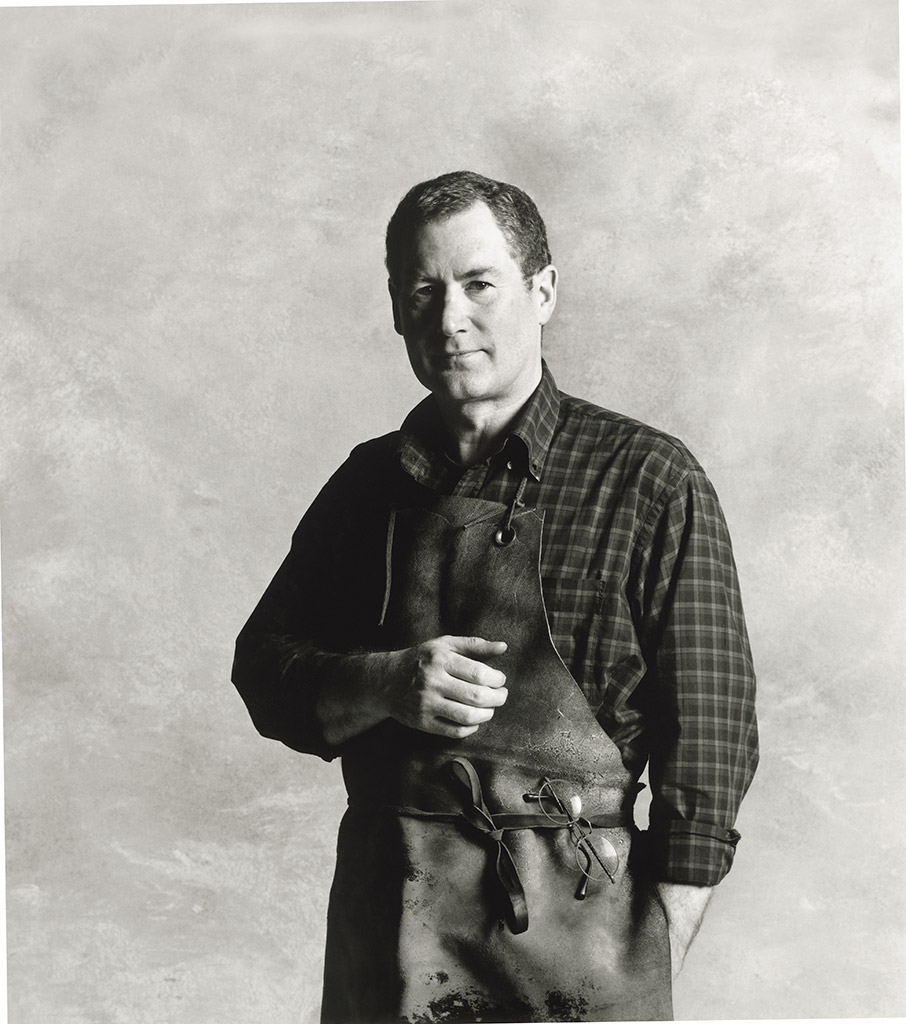

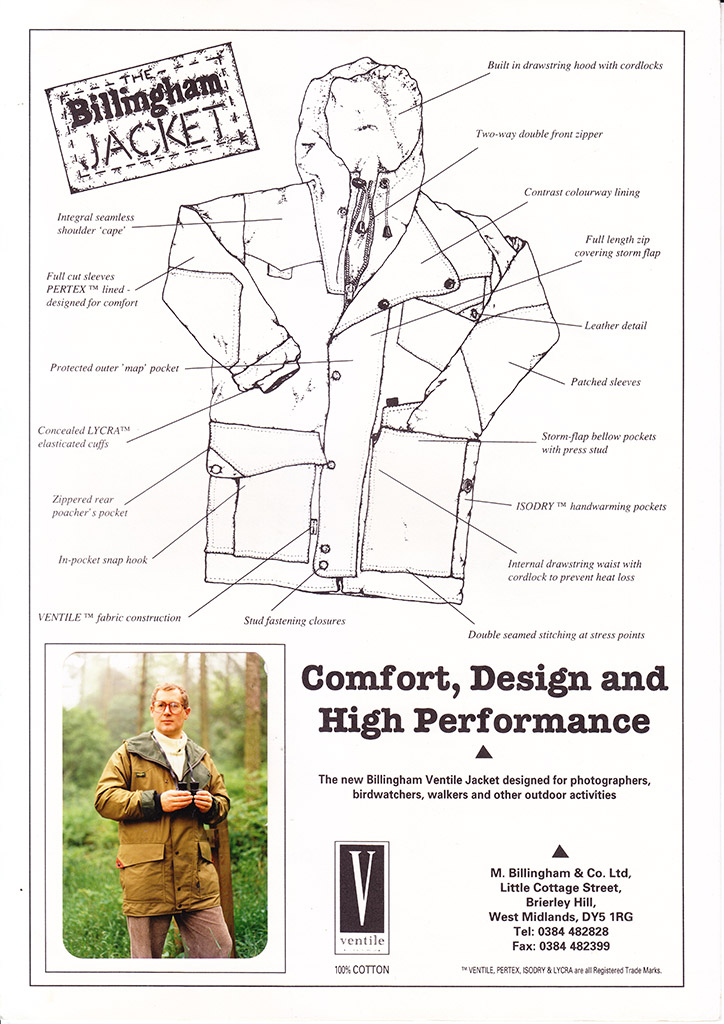

Billingham used to make jackets with Ventile® fabric. The model in the photo is Martin Billingham himself. Circa April, 1991. Photo: courtesy/copyright of Billingham

Leather and brass

It may not look it, but a Billingham bag is a complex piece of engineering. ‘In something like a Hadley there are over 50 individual components,’ explains Martin. There’s the various materials, of course, the inner and outer canvas sandwiching a bonded rubberised layer, the leather and brass, and the inserts. Then there’s all the press-studs and zips and buckles, and three different types of threads used in the stitching. It all adds up.

‘You know the handle on top of the Hadley? There’s something like ten different jigs to actually make that work,’ Martin reveals. ‘And when I designed it, it took me about six months to decide on buying a hot cutter, because there’s a hole cut in the web that goes on top to get the tube in, and if you just chop a hole with something sharp, the web disintegrates. So you need a hot cutter to cut the hole and it was very expensive. But it works fine now.’

Composite image of a photograph of a Billingham 550 camera bag merged with a real x-ray of the same bag with analogue camera gear in. The 550 was Billingham’s first dedicated camera bag, under its previous name of the ‘System 1’. Photo: courtesy/copyright of Billingham

An eye for colour

Consumer habits and priorities have changed over the 50 years that Billingham has been operating. Cameras have become smaller and with that, so have the bags. There’s a greater range of colours as people look for more individuality.

‘The colour choices have been mostly down to our son, Harry,’ says Ros. ‘He’s got an eye for colours and details. But occasionally we’ll see a canvas, they’ll send us a new swatch, and we’ll just look and say that would look nice.’

All of this research and effort costs time and money but there is, nowadays, a different attitude among consumers, and price is not the only motivating factor. People have generally become more discerning when it comes to not only the quality of the product, and the attention to detail, but about how and where the materials are sourced, and the ethics of the firm in general. In a world where few products are made in the UK any more, especially in photography, these societal changes have played to Billingham’s strengths.

Billingham Hadley One Sage FibreNyte with Chocolate leather. Photo: courtesy/copyright of Billingham

‘I think people do have more appreciation of something that’s handmade, and still made in England,’ asserts Martin. ‘And people are more aware of what’s going on in the manufacturing sector and they go out and look for things. They know what they want to buy – not just in the photo trade, but when they buy clothes they’re looking at labels to see what it’s made from.’

Billingham bags at 50

Billingham currently employs 43 people, including the directors. And some of them have been with the firm a very long time. ‘Caroline has been with us 38 years,’ Ros tells us. ‘Mark has been with us for about 35. There’s a few that have been with us for over 20 years, and then many of the rest for 8 to 10 years. And they’re all really lovely people.’

Ros and Martin Billingham today, pictured here with Caroline, their longest- serving employee, who has been with the company for 38 years. Photo: Nigel Atherton

This of course is a great endorsement not only of the products but of Ros and Martin as people and as employers. The whole factory gives off the vibe of a being one big happy family, and there’s a palpable sense of pride in producing something that is considered among the best in the world and exported all over the world. Flags adorn the factory walls from the places to which Billingham bags have been exported. The labels that are stitched into the bags reveal the name of who made them, and they were able to tell me who made not only the Hadley Pro that I was carrying with me on the day of our visit, but also my old Billingham 25 rucksack that I’ve had for over 20 years.

‘They’re really proud of what they do,’ says Ros. ‘They love making something beautiful, and they were just so proud when we won your award (The Lifetime Achievement Award that AP presented to Ros and Martin at the 2023 AP Awards back in February).’ This didn’t really need to be said – it was evident from the little shrine on the factory floor to the 50th anniversary in which their award takes pride of place, surrounded by photos and cuttings.

Product shot of an old Billingham 550 bag showing possible contents. Photo: courtesy/copyright of Billingham

Despite the fact that they’re now in their 70s, and they have in their co-director son, Harry, a safe pair of hands, Ros and Martin appear to still be enjoying themselves far too much to think about retiring. ‘Even after all these years it’s still nice to walk in and see the manufacturing process,’ beams Ros. ‘That’s why we’re still here, still working.’ Martin adds: People always seem to need bags, and there isn’t a perfect bag. So we have to keep designing and making lots of different ones. There are really only two types of bag – too big or too small.’

The label stitched into every bag enables Billingham to identify the person who made it. Photo: Nigel Atherton

Featured photo: A product shot of a System 3 bag, circa 1979, next to some of the tools used to make it. Photo: courtesy/copyright of Billingham

More reading:

Billingham Eventer MKII review

Follow AP on Facebook, Twitter, Instagram, YouTube and TikTok.