Hybrid glass-plastic lenses are tipped to be the next big thing in phone cameras. The iPhone 15 generation, (some would say the best phones), has moved from all-plastic smartphone lenses to a hybrid design. The question that this article addresses is ‘Will this produce better pictures?’

On looking around easily available web sources as to the possible advantages of these lenses, I found that the most obviously cited reason is that glass gives better light transmission, which results in better colour in low light.

Even were it the case that a plastic lens has significantly lower transmission than a glass one, the proposal that replacing just one plastic element with glass would appreciably increase the lens’s overall transmission is, fairly clearly, false. The reason for including glass elements in a design lies elsewhere, but it does have to do with better colour.

The triple lens setup of the iPhone 15 Pro uses a glass-plastic hybrid design. Picture credit: Amy Davies

As with all lens designs, those for phones are shaped by the constraints of their intended application. The biggest constraint is caused by the fact that modern phones are designed to be very slim. This produces a number of knock-on effects. To give a desired angle of view within the available space, a small sensor is required.

With specified resolutions rising, this causes a need for a small f-number, since this determines the amount of diffraction blur in the final image. For instance, to produce 4K video with the sensor sizes that the constraints allow requires an f-number between f/1.4 and f/1.8 for a ‘normal’ lens. As a side note, this is the main reason that phones tend to have ‘fast’ lenses, rather than light transmission.

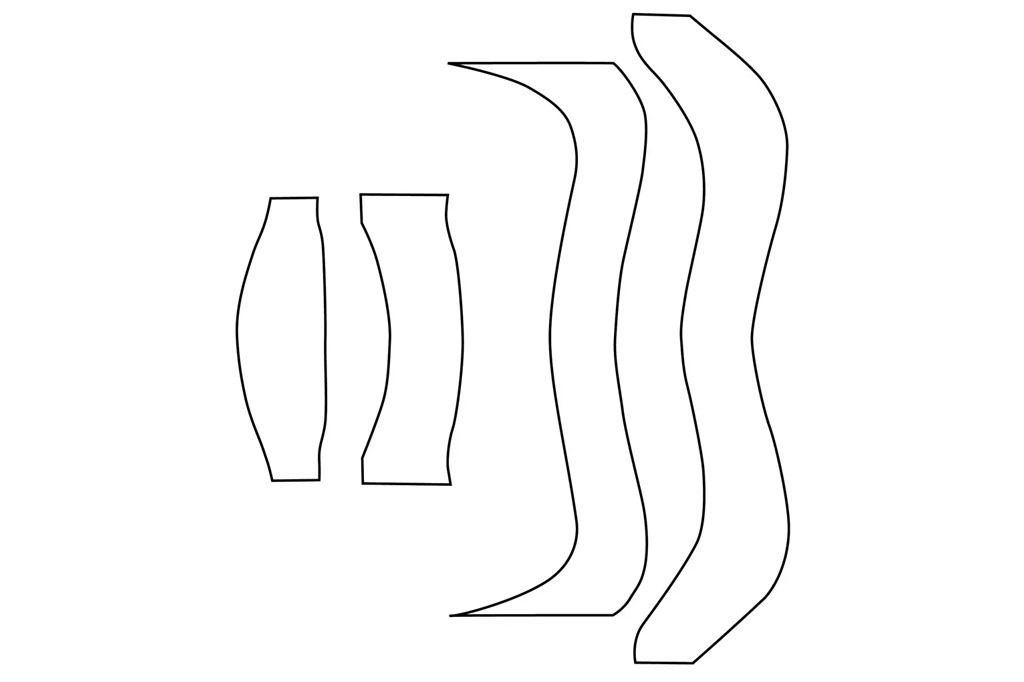

In standard camera-design practice, producing this resolution at such a small f-number would require a lens with many elements. But in a smartphone, this is precluded by the size constraints. Instead, a design of three to six elements can be used, and the spherical aberrations corrected by use of extreme aspheric profiles.

This requirement leads to the choice of plastic materials for making the lens elements.

In practice, it is infeasible to produce this kind of profile to the accuracy and precision required in large production volumes using traditional glass-grinding and polishing techniques, or indeed any kind of glass processing available. Thus the use of optical polymers (plastic), which can be precision moulded in volume, becomes inevitable.

The cost of making the precision moulds is very high, but the production volumes for these camera modules are enormous, so the costs can be absorbed over many units.

A typical phone lens design requires extreme aspherical elements, which can only be fabricated in quantity using plastic moulding techniques.

Colour correction

However, optical polymers do have their limitations. A lens’s colour aberrations are corrected by mixing materials with a range of different refractive indexes and dispersion (how the index changes with wavelength) so as to cancel each other’s unwanted colour effects.

There is only a small range of optical polymers available, and they tend to have small refractive indexes and high dispersions, making it much more difficult to colour correct a plastic lens. When it comes to lateral colour, correction may be achieved using image processing.

However, longitudinal colour cannot be so removed. Including a glass element or two, with a low dispersion, allows its use to counter the high-dispersion plastic elements. Modern glass moulding techniques allow economic production of elements with aspheric surfaces on both sides. While extreme profiles are not possible, those can be reserved for the plastic elements.

The diagram above of a typical smartphone camera lens design, influenced by the patent literature (US7643225B1) shows that there are places in this general design pattern where a moderately aspheric glass element could be used. The resulting lowering of colour aberrations should produce better colour rendition than with all-plastic lenses.

Bob Newman is currently Professor of Computer Science at the University of Wolverhampton. He has been working with the design and development of high-technology equipment for 35 years and two of his products have won innovation awards. Bob is also a camera nut and a keen amateur photographer.

Bob Newman is currently Professor of Computer Science at the University of Wolverhampton. He has been working with the design and development of high-technology equipment for 35 years and two of his products have won innovation awards. Bob is also a camera nut and a keen amateur photographer.

Related reading:

- What is pixel binning, smartphone sensor technology explained

- Are smaller pixels worse? Sensor technology myths explained

- In praise of Bryce Bayer and the supreme Bayer Sensor

Follow AP on Facebook, Twitter, Instagram, YouTube and TikTok.