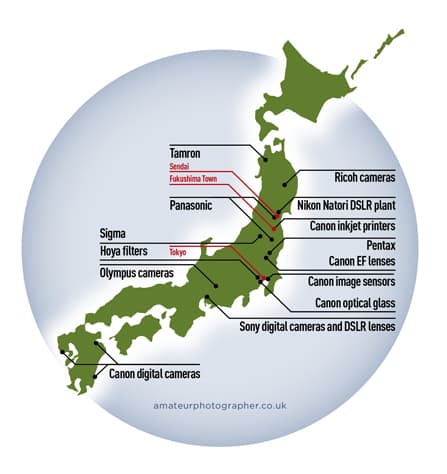

Map charting the impact of the Japanese earthquake and tsunami on camera and lens factories in the Fukushima region and across the whole of Japan

Staff survive, but factories remain shut

Fuel shortages, component supply problems and power blackouts are threatening the return to full-capacity manufacturing in Japan rather than the direct impact of the 11 March earthquake and the following tsunami. Reports from the headquarters of camera and lens brands across the country repeatedly state that while some minor damage has occurred to factories and offices, operations remain suspended in many areas and dates have yet to be set for a resumption of production. Only Nikon has confirmed the death of an employee, from its Sendai plant in the heart of the affected area, while almost all other photo companies have reported minimal injury levels. Nikon has also reported severe damage to its Tochigi plant, said by Nikon to be involved in the ?manufacture of devices and lenses for IC/LCD steppers and scanners?, but it is expecting the facility to be ready for operation by the end of this month (March).

Sigma UK?s Graham Armitage told AP that the company?s factory in Aizu Wakamatsu, in the Fukushima prefecture, was severely shaken but avoided serious structural damage. ?All our employees and their direct families were lucky to avoid death and injury, but the same cannot be said for Sigma?s network of suppliers and subcontractors resident in the Fukushima district.? Mr Armitage explained that, like other photographic brands, Sigma would be hit hardest by the shortage of components. ?If you buy brass washers from a company based close to the shoreline that has been washed away, and you need a brass washer for every lens you make, you can?t go on making lenses until you find another supplier,? he explained. Sigma UK kick-started AP?s Japanese Disaster appeal with a donation of £10,000 worth of equipment.

Canon?s camera manufacturing facilities are based in the south of the country, on the island of Kyushu, and have escaped the worst of the impact. However, the company reports that staff are having trouble getting to work as train services from the mainland are disrupted and there are fuel shortages. The company?s EF lens factory sits in Utsunomiya, Tochigi, south of Fukushima, where operations are suspended with no start date decided. The company says 15 employees were injured there, while the inkjet printer plant in Fukushima reported no injuries, but remains closed until further notice. Sony has four plants in Fukushima, some of which produce rechargeable lithium ion battery cells of the type used in the digital cameras of many other brands. These facilities have also remained closed which may, in the short term at least, lead to delays in the shipment of a wide variety of electronic goods from Japan. Sony?s factories further south, at Aichi and Gifu prefectures, which are responsible for digital camera and DSLR lens production are due to remain closed until at least the end of the month. While not damaged, neither plant has sufficient raw materials or components to continue.

UK distributor Alpha Digital Services has told AP that Ricoh?s Hanamaki plant, in the northern area of Iwate, was largely undamaged, but that operations have been suspended for now. The head office in Toyko is working as normal. ADS also said that a second earthquake on Saturday, measuring 6.1 on the Richter scale, shook the Kyocera factory in Nagano responsible for Contax spares and repairs. In between electricity shut downs, the plant is said to be operating as usual.

Olympus reports that damage to its Shirakawa factory, and unreliable power supplies, have kept it closed, and has given no restart date. The company has given no news of its Tatsuno factory, that makes the E-system products, but we should probably assume that it too is closed.

The events of the past two weeks have had quite an impact on the share prices of photographic companies, with both Nikon and Canon suffering steep declines in their value. Between 4 February and 15 March Nikon?s share price dropped by 30%, while Canon lost 17% over approximately the same period.

Due to the destruction of key plants we will see a slow and unpredictable recovery in this area and we should expect to see shortages of many photo products in the months ahead. A shortage of LCD screens, semi-conductors, imaging sensors, optical lens and flash memory may influence the development of new products. Many companies have stated that should delays continue production facilities could be moved abroad, which may also have a more lasting impact on the Japanese industry. Many firms, such as Nikon and Olympus, already manufacture in countries such as China and Thailand, but even these plants may suffer shortages of key materials.