Polaroid may launch a ?bridge? camera with a built-in printer following the launch of its first digital compact camera to use such technology later this year.

The news comes just days after the firm announced plans to axe instant film production.

Until now Polaroid had been only planning to launch a lower-end compact camera with built-in printer ? expected out later this year with a seven-million-pixel imaging sensor.

?If the prosumer users say we want something which is closer to a bridge [camera] with a very high zoom and different features, we are ready to do that,? revealed Philippe Kalmbach, senior vice president and general manager of Polaroid Europe.

In an exclusive interview with Amateur Photographer Kalmbach said that Polaroid is likely to launch such a product if the demand warrants it and is monitoring the market closely.

The first camera in the range will accept 2x3in paper, fed into the camera via a paper tray. The paper will come in packs of five or ten sheets.

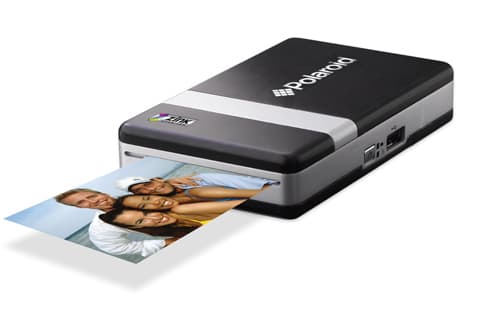

It uses Zero Ink (ZINK) technology, which Polaroid hails as the digital equivalent of instant film.

Similar to dye-sublimation printing, ZINK uses heat to produce an image on special paper.

?ZINK Paper is an advanced composite material with embedded yellow, magenta and cyan dye crystals, activated with 200 million heat pulses, in 30 seconds, in a single pass,? states the technology?s marketing material. ?With 100 billion crystals in a 2x3in print, the paper is 100% inkless.?

The first product to use the system will be a printer (pictured), scheduled for UK launch in June priced £79-99.

Initially, ZINK Paper will come in three sizes: 2x3in, 6x4in and 10x8in.

A launch date for the first of the ZINK-enabled cameras is yet to be finalised, as has the specification. It is expected to cost between £149-199, according to Kalmbach.

Kalmbach said that future cameras may accept larger paper sizes but, this year at least, paper for its first generation cameras will not exceed 6x4in.

?ZINK technology has almost no limitation in size, as the technology lies in the paper itself and is being produced on very large sheets,? Kalmbach told us.