For the latest in our series celebrating the UK’s photographic heritage, Mike Crawford tells the storied history of Ilford Film

I find it difficult to believe I first used Ilford photographic paper in the school darkroom 45 years ago. In the UK, the name is synonymous with black & white photography, and there have been Ilford films, papers and chemicals in production for over 130 years. The brand’s origins date back to 1879, when Alfred H Harman, who ran an early photographic printing business in London, started to manufacture dry plate film, having moved to the Essex town of Ilford.

From Britannia Works to Ilford

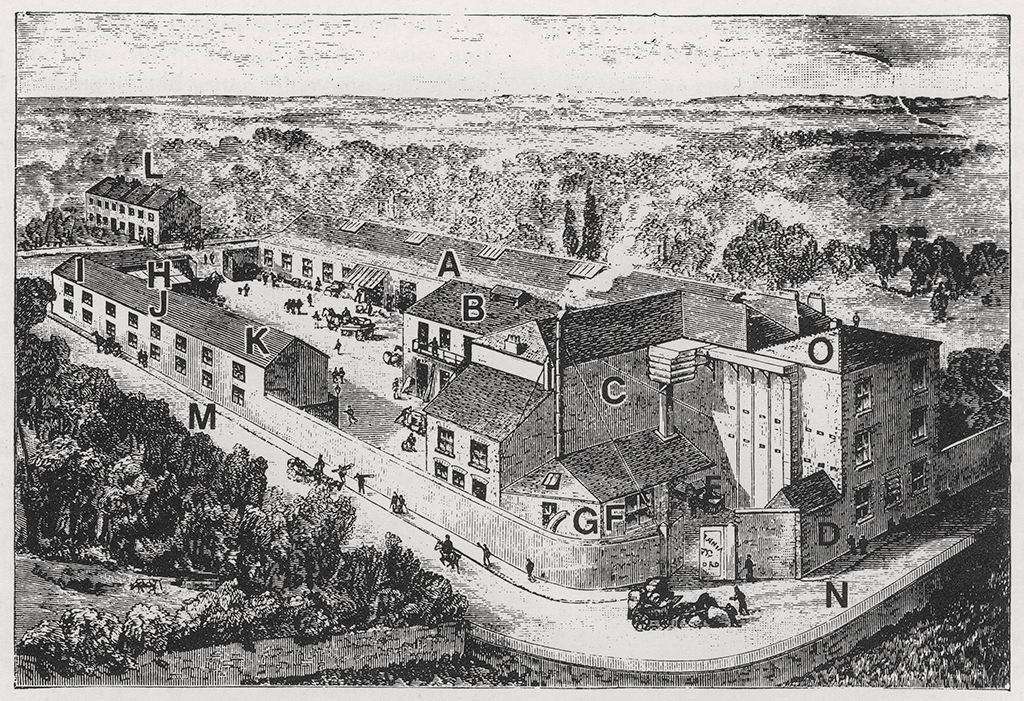

These were sold under the name Britannia Works and in just two years, Harman had built up his company, opened several factories and extended the range of products to include photographic papers, registering his business as a limited company in 1881. In 1886, following legal disputes, his products were renamed Ilford, two years before the trade name Kodak was registered, making it one of the oldest photographic brands in constant production. (Tetenal in Germany dates back further to 1847.)

For more than 100 years, Ilford continued to expand, having absorbed and conglomerated several smaller photographic manufacturers. The company name was changed to Ilford Limited in 1902, by which time Harman had sold his shares in the company. Expansion followed over the decades and while a complete history of Ilford is perhaps too involved to cover in detail, it should be noted that by the 1970s, Ilford was a global company, with bases in the UK, Switzerland and France with over 6,000 employees.

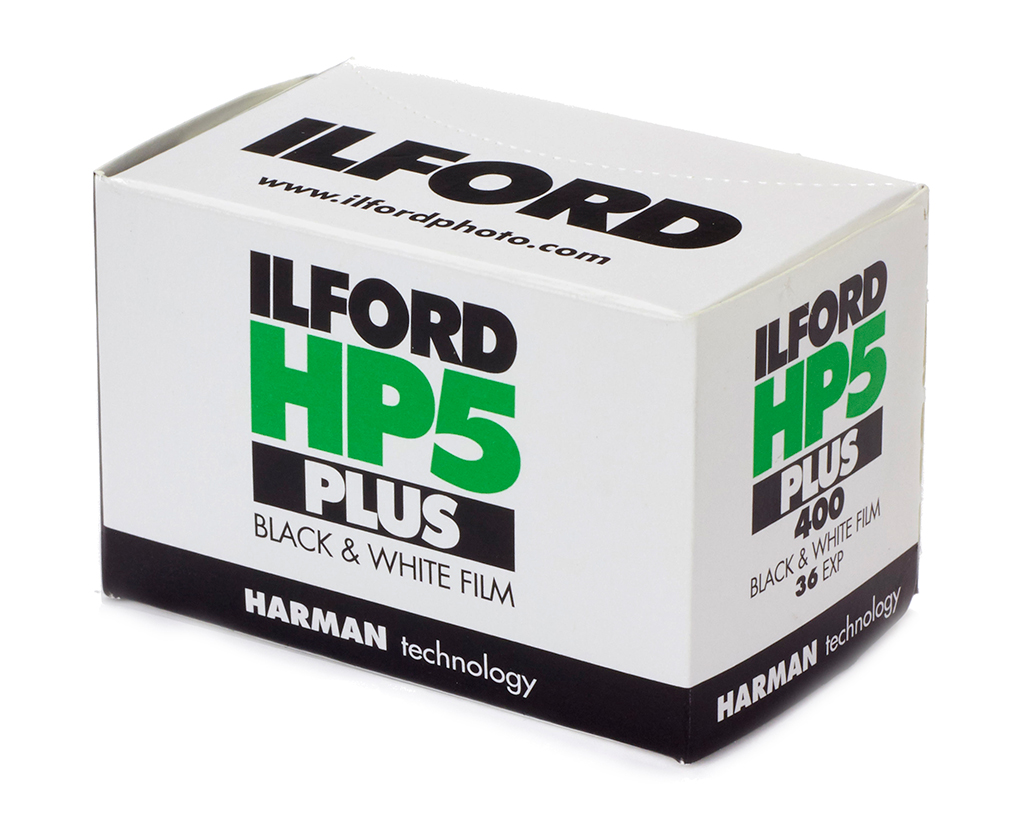

HP5 Plus is a classic, fine- grain, high-speed black & white film. Harman Technologies produces 11 different Ilford black & white films

There have been several different owners of the company since Harman’s death in 1913. Throughout that time, Ilford has continued to innovate and produce world-renowned black & white materials. By 1983, its factory and HQ had moved to Mobberley, Cheshire, in the grounds of the old Rajar factory, a smaller company acquired in 1928.

Management buyout

One of the most pivotal moments in its recent history was in 2005. Forced with the prospect of liquidation, due to the rise of digital and falling sales, a group of six Ilford managers took the bold step of buying out the company from the receivers. This effectively saved the factory and Ilford’s film, paper and chemical products, with a new company formed named Harman Technology Ltd. While reduced in size, it has prospered with the growing interest in analogue photography over the past ten years and now exports to over 90 countries.

The company was sold to Pemberstone Ventures Ltd in 2015, and continues to operate from its manufacturing base in Mobberley, producing both Ilford, Kentmere and more recently Harman products. I recently had the opportunity to speak online to Michelle Parr and Matt Parry from their marketing department on the continued success of the Ilford brand and the challenges faced during the past few years.

The original Britannia Works factory at Ilford, Essex, taken from an 1888 engraving originally published in the British Journal of Photography

The modern operation

‘Our company name is Harman Technology though we trade under Ilford Photo and our products are mostly Ilford brands,’ Matt told me. ‘One of the reasons we survived and other larger companies did not, was that we were able to make our operation more scalable and flexible so we could adjust and adapt to different volumes. We have had consistent growth now for seven years or more, driven by sales of film.’

The renewed interest in film and analogue photography has been aided and complemented by the growth of social media platforms and the ability for people to share information and knowledge within a like-minded community. This has become an integral part of Harman and Ilford Photo’s marketing and communications. ‘Using social media, and our website, which everything is linked to, gives us a global reach and audience for our products,’ confirmed Matt. ‘This is the difference between now and 15 years ago. In doing so we have two main aims: to educate and to inspire. We try to give the basics, then more advanced, but also offer inspiration in what other people are doing and how they use our film and paper to create something unique.’

Michelle mentioned that they are very active on all main outlets – Instagram, Facebook, YouTube and Twitter – and added the importance of communicating with their customers. ‘The most popular video on our YouTube channel for the past eight months has consistently been “Making your first darkroom print.” We talk to our customers as there is no point in us just saying what people want.

We have really good relationships with film shooters and printers in the community and ask them what they want to see. We are very approachable through social media and people feel that they know us. I use the word a lot, but I really think there is a community of film shooters out there and generally they’re a friendly bunch. They are welcoming and happy to give advice and to help out someone new asking questions.’

Getting started with printing

Without good instruction, the first steps into printing may seem daunting. ‘There is a perception of the learning curve required when starting to print,’ agreed Matt. ‘Anyone can pick up a film camera and shoot but there is an idea that printing is somehow less accessible, but it’s quite straightforward to make a darkroom at home from basic materials. One struggle is access to affordable enlargers, though something like the Intrepid Enlarger is a good stepping stone.’

This is particularly relevant to further education in universities and colleges. Indeed, after the management buyout in 2005, I was involved, with other printers, giving Ilford workshops around the country. ‘Education is very important, but it’s not just the teaching of skills but also sharing the enthusiasm,’ Michelle emphasised. ‘We see that with our student competition. We get entries from all over and the best work comes from where the lecturers and technicians are really involved. It’s not just a job for them but a passion. They enjoy being in the darkroom and sharing their knowledge.’

‘Colleges and universities are big users of our paper,’ added Matt. ‘It was a challenge during the pandemic as schools, college, university and community darkrooms were all shut. While film stayed very consistent to 2019 figures, which was our best year for many years, paper took a hit with darkrooms being closed.’ Inevitably our conversation changed to the problems faced during Covid-19.

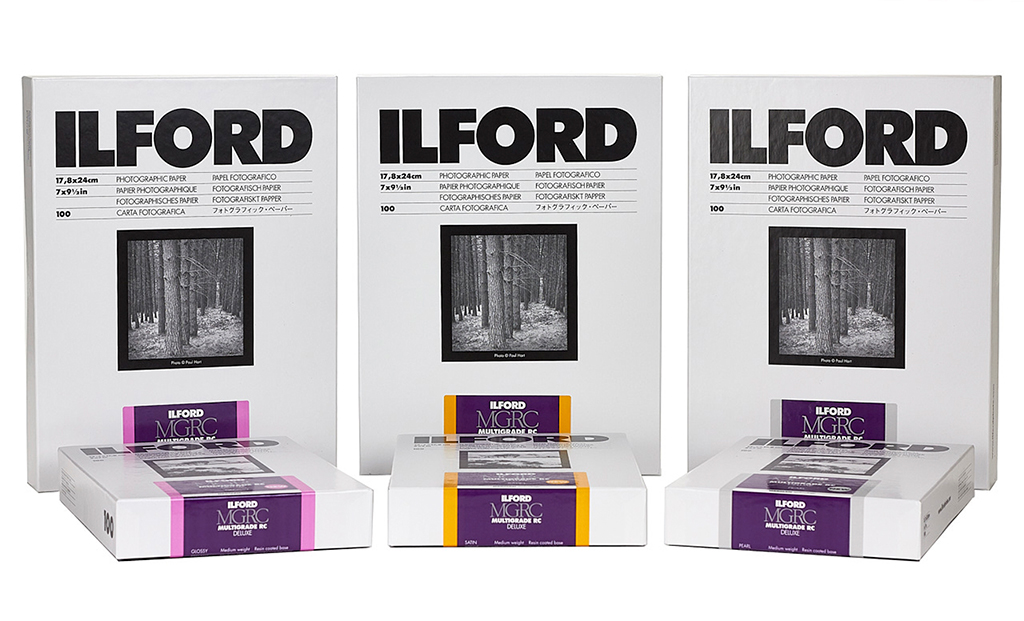

The first Ilford Multigrade paper was produced in 1940. Subsequent versions followed, with the fifth generations of papers being introduced in 2013 for Fibre Based (FB Classic) and 2020 for Resin Coated (RC Deluxe). Other Ilford papers include Warmtone FB and RC, Cooltone FB and RC and Art 300

Read more about paper for film printing: Choosing the best paper for film printing

Working through the pandemic

‘When it started, no community darkrooms were open so there was a definite need to learn online,’ Michelle told me. ‘We were luckier than a lot of businesses as our products were still accessible. Before shutting down for two months, we ensured there was plenty of stock and that dealers were supplied. We were very proactive during this time, such as Matt filming a YouTube video at home with his son. People were looking for things to do and shooting film and processing it was ideal. So many processed their first film during lockdown.’

‘We were told by our dealers and distributors that during Covid we were consistent,’ Matt said. ‘Film as a product is relatively low value but high volume. Film sustained a lot of the photographic retail and distribution networks in the marketplace. Many said if it hadn’t been for our products and those from other film makers, their firms might not be here today, which shows the popularity of analogue and processing at home.’

Both Michelle and Matt emphasised and credited the skill and dedication of their workforce and the importance of recruiting new staff. ‘They have a lot of knowledge,’ Matt remarked. ‘There are scientists, graduates and apprentices working in R&D and we’re actively looking at the next generation of engineers to continue making the products. New people are needed to learn from those with 30 years or more experience, making sure we have the right people to make the products consistently.’

As usual, there are plans for new products and initiatives. ‘We always have more ideas than we could ever do,’ Michelle said. ‘Over recent years we have launched things like the Harman reusable cameras, our fifth-generation Multigrade RC papers, our Ortho film and our new Pop-Up Darkroom. We’ve also produced a Film Processing Starter Kit with Paterson and are soon launching the Darkroom Starter Kit.’ For myself, it is reassuring and important to know that the classic Ilford brand of papers and films, with such an impressive history and heritage, continue to be produced, having spent so many years using them and with the intention of many more to come.

I’ve used Ilford films for as long as I can remember. My main choice of films are HP5 Plus, FP4 Plus and Delta, 3200. Berlin, 1998, Rolleiflex 2.8E, Ilford HP5 Plus film. Image: Mike Crawford

Ilford Logo and Branding

When the brand name Ilford was chosen in 1886, its first recognisable logo, or trademark of a paddle steamer, soon appeared on packaging. The simplified version shown here was its last iteration used from 1930. This was replaced by the Sunburst symbol in 1964, along with colour coding for different film speeds, while the familiar, bold lettering, still in use today, first appeared in the 1970s.

Behind the Film documentary

Ilford Photo’s YouTube channel has many inspirational videos to watch. Notable is the work by Sarah Reyes and Daniel Driensky of Exploredinary, (exploredinary.com), who have made several short films on Ilford, including Behind the Film. This takes the viewer on a tour of the Mobberley factory, meeting some of the engineers, technicians and other employees involved in producing Ilford products, plus visiting the emulsion making, R&D, quality control and other departments. youtube.com/Ilfordphoto.

To check out more from Ilford or purchase film visit ilfordphoto.com

Or follow them on social media: Instagram, Facebook, YouTube, Twitter: @ilfordphoto

Related articles:

The Royal Photographic Society: a prominent heritage of photography for all – Amateur Photographer

Edward Reeves Studio: inside the world’s oldest photographic studio